Data Dasar

Tipe Dasar:

1.Insulated gaya konduktor tunggal

2. Gaya konduktor kembar

3.Un-insulated ari tungtung sleeves

Ciri

Total cross-bagian: 0,25 ~ 150mm²

Warna-coding sareng dimensi tabung ka DIN 46228, bagian 4 (0.5 ~ 50mm²)

Halida bébas, seuneu retardant bisa nampa

Tahan panas ka 105 ℃ (PP) 120 ℃ (PA)

Bahan:

99% Tambaga murni

Sintétik: Polipropilén (PP), Poliamida (PA)

Beungeut

Tin-plated ngajaga ngalawan korosi

Inpo pesenan

Ayeuna ogé sayogi dina kotak plastik gunana pikeun syarat anu langkung alit.Dina kaayaan normal urang teu boga sarat MOQ pikeun bungkusan kantong.

Data Téknis

Bahan Conductive (iwal Gancang Connect Range)

| Tambaga | 99,9% murni |

| Kakuatan regangan | 200MPa |

| Peunteun ductile | 35% |

| Nagara Metal Pamungkas | Bagian tina produk annealed |

| Kandungan Oksigén | 50ppm max |

|

|

|

| Kuningan | 30% Séng 70% Tambaga |

| Kakuatan regangan | 580 Mpa |

| Peunteun ductile | 6% mnt |

| Nagara Metal Pamungkas | Bagian tina produk annealed |

|

|

|

| Bahan | Tin |

| Kandungan Tin | 99,90% |

| Logam lianna | Timbel + Antimony |

| Ketebalan Plating | 1,5 mikron |

|

|

|

| Konduktivitas Umum | 98,5% IACS |

| Résistansi total | 1,738 mikro-ohm cm |

|

|

|

| Bahan | PVC pikeun sakabéh iwal nilon 6 atanapi nilon 66 - pikeun IQC |

| tegangan ngarecahna | 1,5 k V (mnt) |

| lalawanan insulasi | Di luhur 100 meg ohm |

| tegangan gawé | Nepi ka 300V AC/DC |

|

|

|

| Pra-Insulate | -40 ℃ nepi ka + 150 ℃ |

| Kuningan | 145 ℃ |

| Dilapis timah | 160 ℃ |

SPESIFIKASI

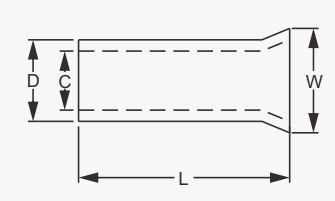

| bagian melintang (mm²) | Item No. | Diménsi (mm) | AWG |

| bagian melintang (mm²) | Item No. | Diménsi (mm) | AWG | ||||||

| L | W | D | C |

| L | W | D | C | ||||||

| 0.25 | EN0206 | 6 | 1.5 | 1.1 | 0.8 | #26 |

| 10 | EN10-18 | 18 | 5.8 | 4.9 | 4.5 | #8 |

| EN0208 | 8 |

| EN10-20 | 20 | ||||||||||

| 0.34 | EN0306 | 6 | #24 |

| EN10-25 | 25 | ||||||||

| EN0308 | 8 |

| 16 | EN16-12 | 12 | 7.2 | 6.2 | 5.8 | #6 | |||||

| 0.5 | EN0506 | 6 | 1.7 | 1.3 | `1.0 | #22 |

| EN16-16 | 16 | |||||

| EN0508 | 8 |

| EN16-18 | 18 | ||||||||||

| EN0510 | 10 |

| EN16-20 | 20 | ||||||||||

| EN0512 | 12 |

| EN16-22 | 22 | ||||||||||

| 0.75 | EN7506 | 6 | 1.9 | 1.5 | 1.2 | #20 |

| EN16-25 | 25 | |||||

| EN7508 | 8 |

| 25 | EN25-12 | 12 | 9.1 | 7.9 | 7.5 | #4 | |||||

| EN7510 | 10 |

| EN25-16 | 16 | ||||||||||

| EN7512 | 12 |

| EN25-18 | 18 | ||||||||||

| 1.0 | EN1006 | 6 | 2.2 | 1.7 | 1.4 | #18 |

| EN25-22 | 22 | |||||

| EN1008 | 8 |

| EN25-25 | 25 | ||||||||||

| EN1010 | 10 |

| 35 | EN35-16 | 16 | 10.2 | 8.7 | 8.3 | #2 | |||||

| EN1012 | 12 |

| EN35-20 | 20 | ||||||||||

| EN1018 | 18 |

| EN35-25 | 25 | ||||||||||

| 1.5 | EN1508 | 8 | 2.5 | 2.0 | 1.7 | #16 |

| 50 | EN50-12 | 12 | 12.7 | 10.9 | 10.3 | #1 |

| EN1510 | 10 |

| EN50-18 | 18 | ||||||||||

| EN1512 | 12 |

| EN50-22 | 22 | ||||||||||

| EN1518 | 18 |

| EN50-25 | 25 | ||||||||||

| 2.5 | EN2506 | 6 | 3.3 | 2.6 | 2.3 | #14 |

| 70 | EN70-22 | 22 | 15.8 | 14.3 | 13.5 | 2/0 |

| EN2508 | 8 |

| EN70-25 | 25 | ||||||||||

| EN2510 | 10 |

| EN70-32 | 32 | ||||||||||

| EN2512 | 12 |

| 95 | EN95-25 | 25 | 17.3 | 15.6 | 14.8 | 3/0 | |||||

| EN2518 | 18 |

| EN95-30 | 30 | ||||||||||

| 4 | EN4009 | 9 | 3.9 | 3.2 | 2.8 | #12 |

| EN95-34 | 34 | |||||

| EN4012 | 12 |

| 120 | EN120-30 | 30 | 20.2 | 17.7 | 16.7 | 4/0 | |||||

| EN4018 | 18 |

| EN120-34 | 34 | ||||||||||

| 6 | EN6010 | 10 | 4.7 | 3.9 | 3.5 | #10 |

| EN120-38 | 38 | |||||

| EN6012 | 12 |

| 150 | EN150-32 | 32 | 23 | 20.6 | 19.6 | 250/300 | |||||

| EN6018 | 18 |

| EN150-40 | 40 | ||||||||||

| 10 | EN10-12 | 12 | 5.8 | 4.9 | 4.5 | #8 |

| 185 | EN185-32 | 32 | 23.9 | 21.4 | 20.2 | 300/350 |

| EN10-16 | 16 |

| EN185-40 | 40 | ||||||||||